WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Size accurate, seamless forming

Various models customizable, meet diverse needs

Fast production speed, high efficiency

Automatic control, reduce labor costs

Stable operation, high precision, long service life

Email:jodie@hx_machinery.com

Mobile Phone:0086_18920395263

Automatic Metal Stud Machine

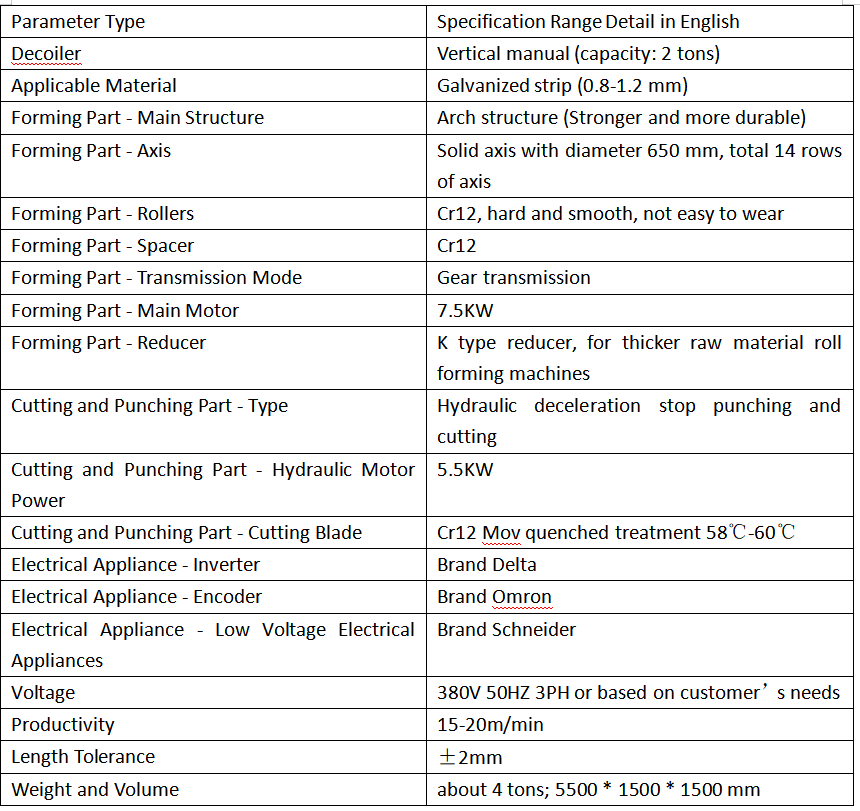

The Automatic Metal Stud Machine is a high-efficiency, intelligent equipment specialized in the continuous production of standard and customized metal studs. Equipped with an advanced servo control system, it realizes fully automated workflow—from coil material uncoiling, leveling, and precise roll forming to automatic length measurement, hydraulic cutting, and finished product collection—ensuring uniform stud dimensions, flat surfaces, and strong structural stability that comply with global construction material standards.

This machine supports flexible processing of multiple metal materials, including GI (Galvanized Iron), GL (Galvalume), PPGI (Pre-painted Galvanized Iron), and PPGL (Pre-painted Galvalume), with a material thickness range of 0.3-1.2mm. It is widely used to manufacture metal studs for wall framing, ceiling grids, and partition systems, perfectly adapting to the diverse needs of residential, commercial, and industrial construction projects.

Parameter Type Specification Range Application Scene

Material Type GI/GL, PPGI/PPGL Wall Framing, Ceiling Grids

Material Thickness 0.3-1.2mm Residential/Commercial Construction

Forming Speed 15-50m/min (Adjustable) Mass Production of Metal Studs

Finished Stud Length 1.2-6.0m (Customizable) Partition Systems, Interior Decoration

Constructed with a heavy-duty steel frame, its core components—such as 40Cr alloy steel forming rollers (with chrome plating for wear resistance) and high-hardness tungsten steel cutters—guarantee stable operation, low maintenance frequency, and a service life of over 8 years. With an adjustable forming speed of 15-50m/min, it significantly improves production efficiency (30% higher than semi-automatic models) and reduces labor costs, as only one operator is required for full-process monitoring.

Featuring a user-friendly touchscreen interface, this machine allows easy parameter setting, production data tracking, and fault alarm display—simplifying operation and reducing training time for workers. It is an essential equipment for construction material manufacturers aiming to enhance production capacity, ensure product consistency, and gain competitive advantages in the fast-growing light steel construction market.

Contact us now via WhatsApp (+86 138xxxx5678) or Email (sales@metalstudmachine.com) to receive a tailored quotation and professional technical support!